Identification number on a steel billet

AI built for the realities of steel manufacturing

Zurich-based SMS Concast specializes in manufacturing plants for the steel production process, specifically casting semi-finished long products out of steel, like billets, beam blanks, and blooms. Each billet receives a unique identification number, indicating production details and specific characteristics. In 2007, SMS Concast approached CSEM to co-develop a solution, supported by the Swiss Commission for Technology and Innovation (CTI). CSEM, with over 25 years of expertise in artificial intelligence (AI) enabled vision systems, designed a vision system incorporating a three-color illuminator and trained it using machine learning techniques. This system, known as “Steeltrack” has been successfully implemented by numerous steel plants around the world over the past decade.

Outdoor stocking of steel billets

Efficiently bypassing rust and dust

Taking advantage of advancements in AI, CSEM was approached again by SMS Concast a decade later. Their goal was to develop a system with enhanced accuracy and cost-effectiveness for reading the billet serial numbers, particularly in harsh environments with challenging conditions with temperature changes and dust. Identifying billets and their materials becomes challenging after months or years of outdoor storage, as rust and pollution can alter the embossed unique identification number (or OCR for optical character recognition), resulting in incomplete and/or unreadable serial numbers.

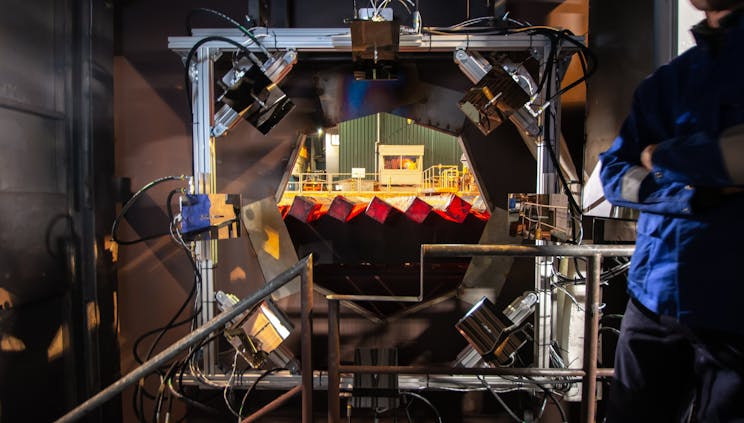

Prototype of the vision system developed by CSEM.

Proprietary and AI-based Vision System

This time, CSEM’s engineers created a proprietary vision system equipped with camera acquisition to read the elements of the serial numbers. Through customized algorithms and intelligent data processing, the system can identify all the necessary characteristics of a billet, even with incomplete serial numbers. The result is a highly robust and reliable billet “detector” prototype solution with an impressive accuracy rate of 99.8%, surpassing the performance of the initial solution.