5 June 2025

CSEM and Ifremer collaborate to advance deep-sea exploration with underwater lidar technology

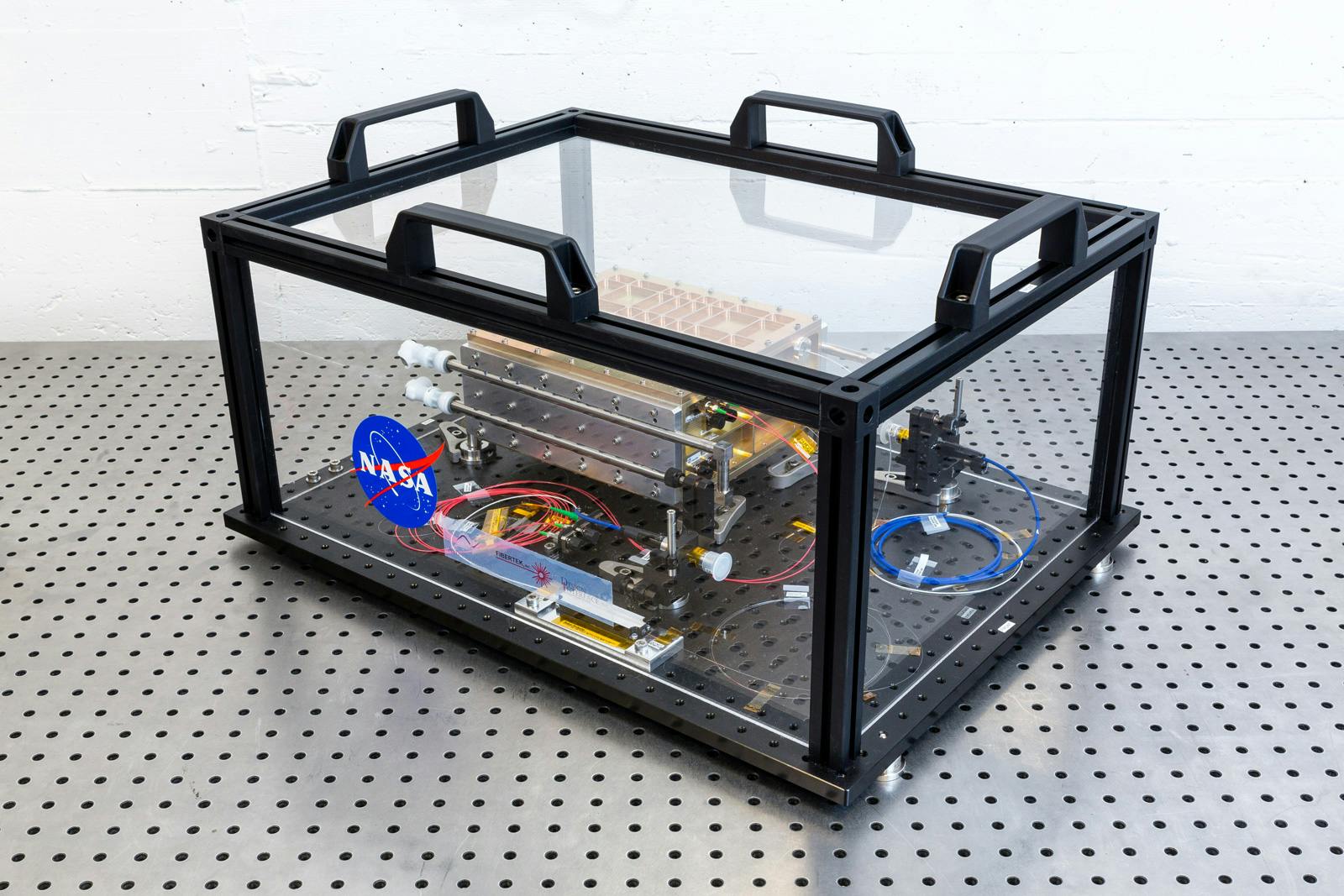

In partnership with Ifremer, the French Research Institute for Exploitation of the Sea, CSEM is developing an underwater lidar system to map and explore the deep-sea environment.