June 22, 2021

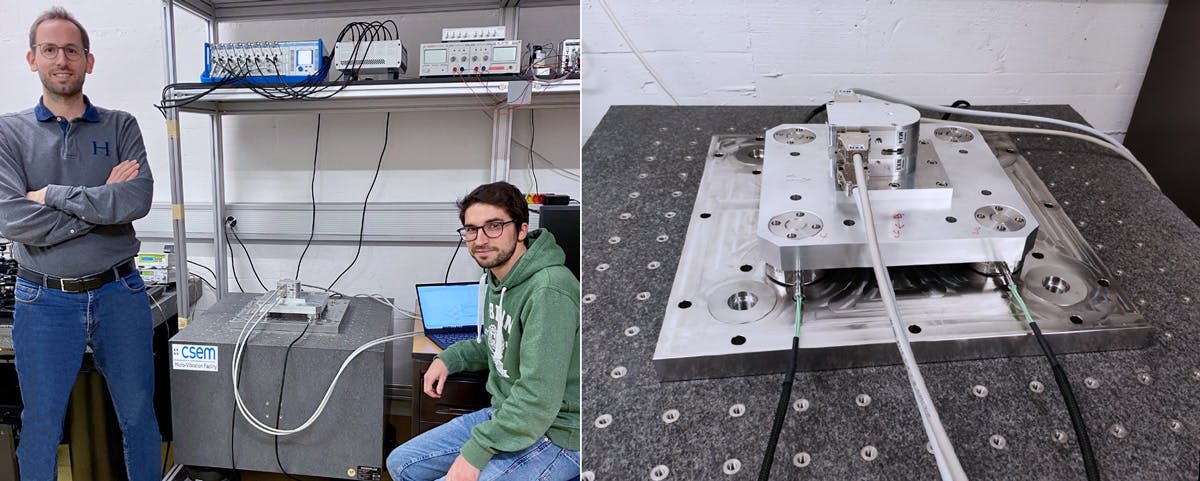

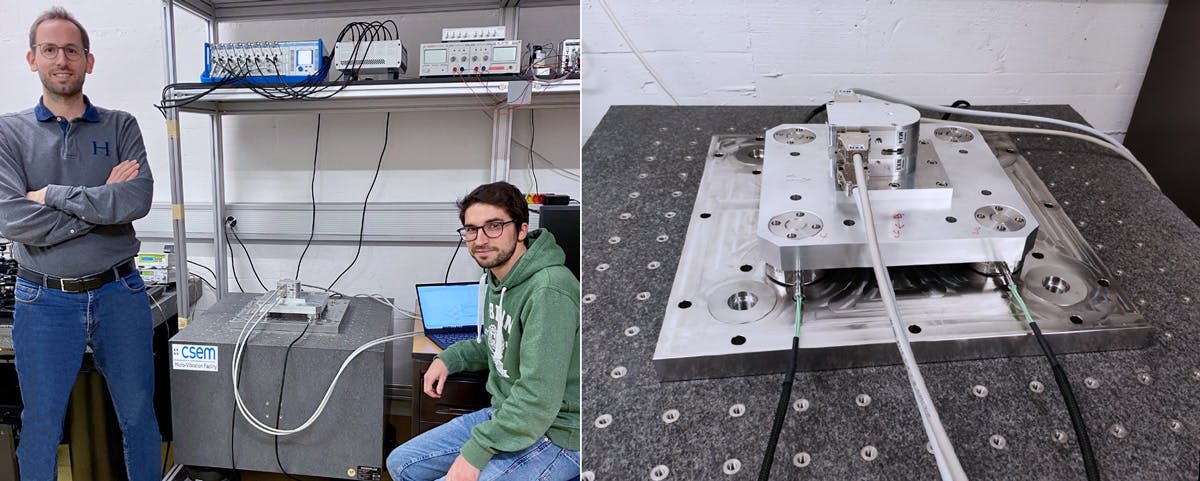

Smoothing the way for space components

CSEM has developed a new micro-vibration test bench, which is capable of accurately characterizing the vibrations generated within space apparatus while researching the use of magnetic bearings for satellite attitude control. Smoothing the ride for sensitive space components is of critical importance. Over time low-level vibrations and small disturbances can lead to the degradation of high-precision optical space instruments, ultimately affecting their performance.