Easy to integrate into mechanically pumped loops: The 150-millimeter pipe segment weighs only 115 grams and was additively manufactured.

Hervé Saudan, Group leader Precision Mechanisms at CSEM and coordinator of AHEAD, explains: “Thanks to Design for Additive Manufacturing, we implemented built-in wires to heat the segment. Through the wires’ arrangement, we achieve optimum heat transfer all around the tube, whereas conventional film heaters only heat a limited area.”

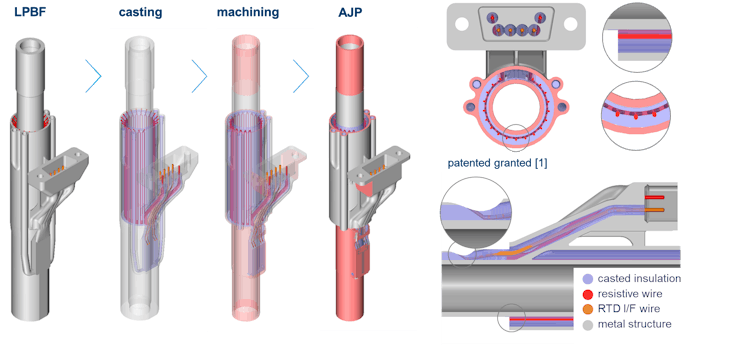

Another advantage of the pipe segment is that it is easy to install into an MPL, as the heater, sensor, and connector are already part of the pipe. This could only be realized through an innovative manufacturing concept involving laser powder bed fusion (LPBF), resin injection and machining.

Pipe design detail: note that the structure, the connector as well as the heating and routing wires are all 3D printed in the same step with the same material (316L stainless steel).

Integrating functionality through high precision 3D-printing

CSEM microtechnology experts have utilized all current design freedom offered by LPBF, a 3D printing method. In their design, they integrated sets of wires for both electrical heating and the routing of the sensor signals: “The structure as well as the wiring and connector are 3D printed altogether in one step,” Hervé adds. Consequently, such a concept renders complicated bonding and wiring processes obsolete, eliminating the risk of delamination and disconnection of cables too.

To make the concept feasible, the main challenge was to define a way to 3D print thin and long electrical wires together with the pipe structure, while ensuring that in its final state, the wires and said structure are not electrically connected. To achieve this, the design involves sacrificial bridges which provide mechanical stability to the wires. These bridges are machined once the insulation has been injected and cured. For this original design and manufacturing method, Hervé Saudan and his colleague Lionel Kiener filed a patent.

More reliable and convenient architecture

- No adhesive, no screws, no additional parts

- No assembly, i.e. no delamination / breakup

Design freedom

- Any shape : tubular, flat, complex curvature

- Heater optimized to your specific design

Performance

- Better heat transfer, high power density

- Heating above 1000°C with casted ceramic insulation

Functionalization

- Heat exchange and insulation design features can be added

- Temperature sensor can be integrated based on the same concept

Independence and uniqueness

- Free yourself from dependence on a supplier

- Regain complete control of your design

- Secure your USP thank to a patented design and manufacturing concept

About AHEAD

The AHEAD project (Advanced Heat Exchange Devices) aims to revolutionize thermal control systems – critical components of a number of high-performance devices like satellites and space rockets.

Most thermal control systems in use today are heavy, and bulky and require a myriad of connection cables. With AHEAD, the goal is to develop systems that are compact, less expensive and wireless, allowing for real-time data collection and improved efficiency.

Optimizing the materials

For future space applications, the structure of such tube segments might be out of Aluminum to reduce weight further. Other interesting materials are cast ceramics as insulation material because it withstands temperatures up to 1000 degrees Celsius) and sustainable insulating materials like bio-sourced resins.

Get in touch

Are you interested in more details or other projects? Discover our Instrumentation activities or contact our experts at info@csem.ch