Take the next step in your photonics journey

Reach out to us for a consultation and discover how we can tailor solutions to meet your specific needs.

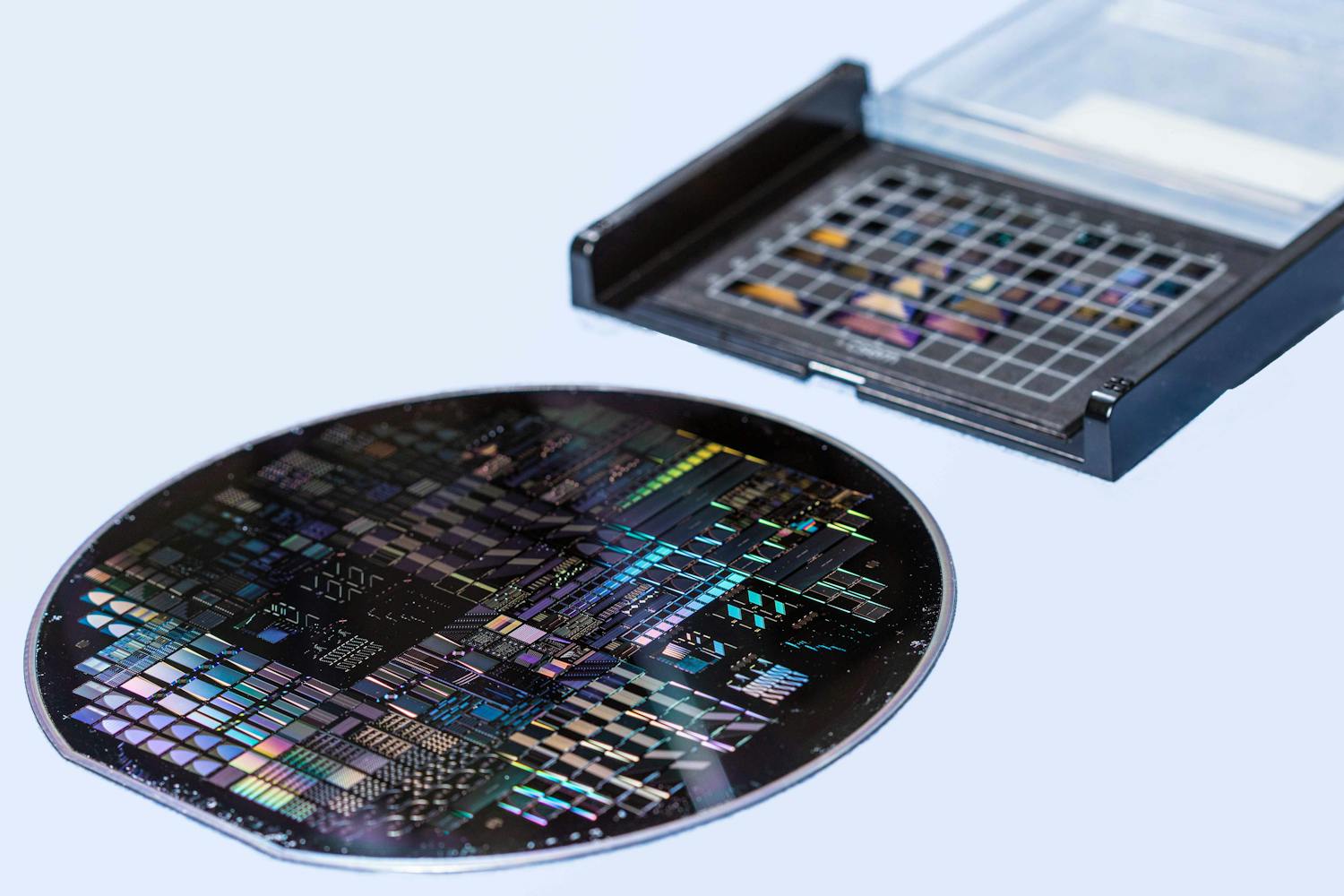

CSEM supports the photonic community with various services based on its standardized TFLN PIC platform, dependable process design kit (PDK) and a 150 mm wafer-scale fabrication process, which includes PIC design, manufacturing, and testing.

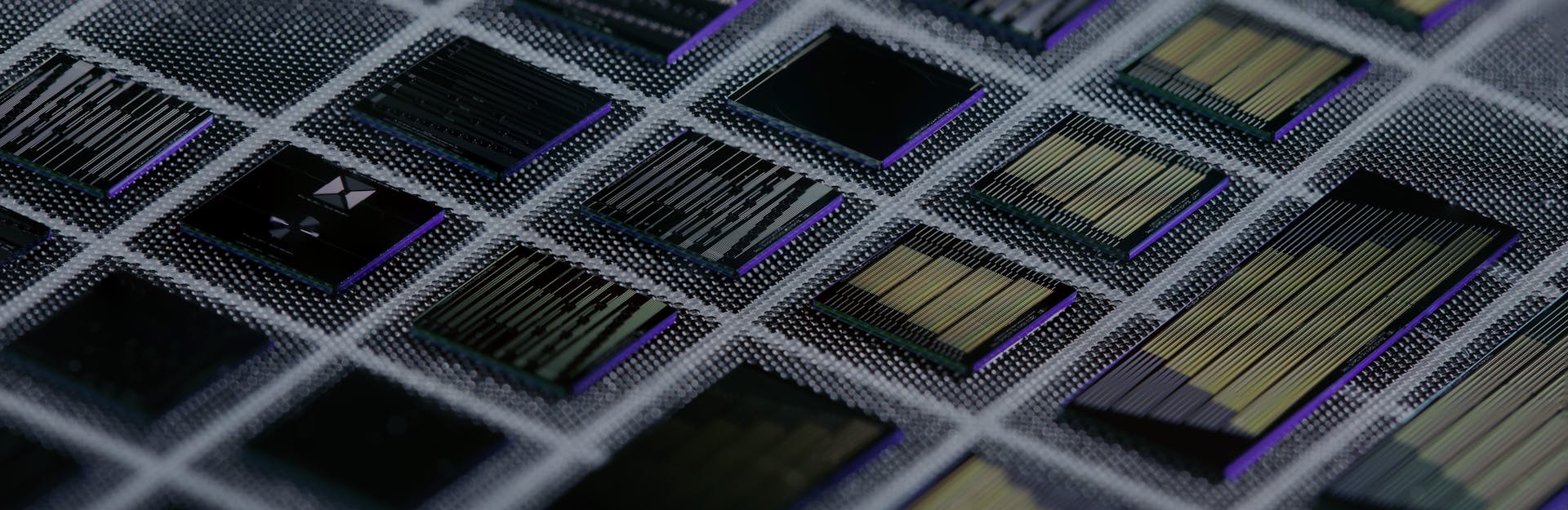

CSEM was among the first to introduce an open-access foundry service for standardized TFLN PICs (Thin-Film Lithium Niobate on Insulator Photonic Integrated Circuits), designed specifically for prototyping, and research and development. The distinctive features of this service include a unique combination of three device layers, two metallization steps, cladding, back-end-of-line opening steps, and seamless chip facets integrated into a monolithic PIC platform.

This integration opens up a myriad of possibilities for intricate PIC designs, as well as hybrid and heterogeneous integration. Moreover, it facilitates easy electrical and packaging interfacing.

Our state-of-the-art technology and expertise in the PIC domain ensure superior quality and performance for applications in telecommunications, data centers, quantum, and beyond. Now is the time to partner with CSEM to leverage the potential of TFLN in your innovative projects.

Learn how Miraex leveraged our TFLN foundry services for breakthrough photonics solutions.

CSEM TFLN PIC foundry services is supported by a dependable process design kit (PDK) on telecommunication C-band. The PDK encompasses a set of active and passive building blocks, technology layers and design guide documentation.

Furthermore, CSEM provides the PIC designer with parametric cells (PCell) for the building blocks. This enables the designer to turn the standardized components into customized ones (in compliance with the fabrication design rules), easing the layouting and circuitry of the customized PICs.

CSEM's TFLN PIC foundry service covers design, manufacturing, and testing needs.

Reach out to us for a consultation and discover how we can tailor solutions to meet your specific needs.