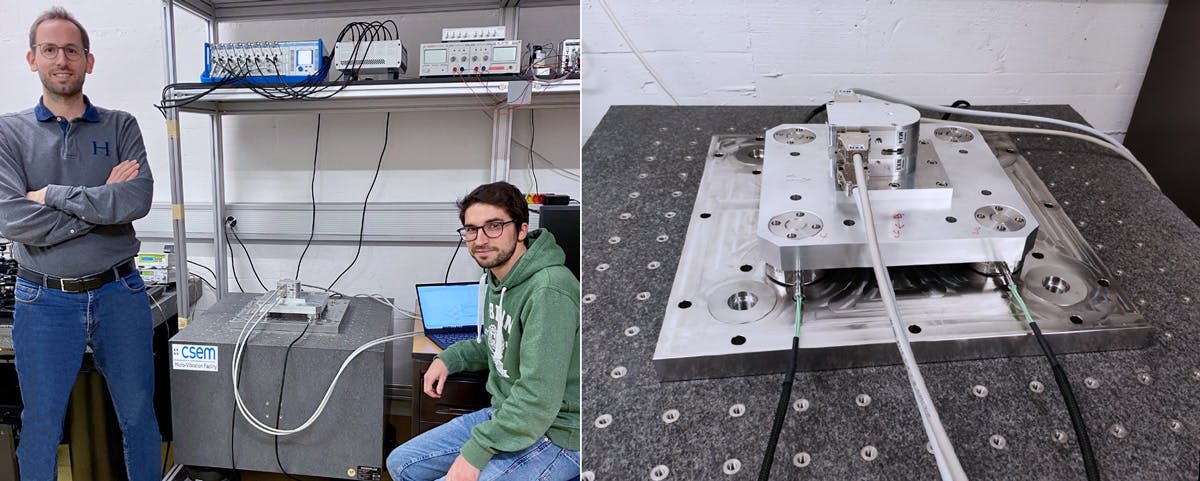

“To give an idea of scale, when we mention micro-vibrations, we mean within the millinewton range, we needed to have a highly sensitive measuring chain with very low noise. Kistler’s sensors and charge amplifier were perfect for this job and provided us with the high-quality results we needed,” remarks Guzmán Borque Gallego from CSEM. “We were really impressed by the way Kistler’s technology could cope with conditions that were beyond its given constraints, it’s incredibly robust,” adds Leopoldo Rossini, the previous head of CSEM’s micro-vibration facility.

With the support of Kistler’s measurement technology, CSEM’s engineers were able to comprehensively study a prototype reaction wheel with a magnetic bearing from the Swiss company, Celeroton. Their cutting-edge wheel technology is friction-free, meaning it has a virtually infinite lifetime. It can also actively suppress unwanted vibrations by control, allowing it to achieve higher performances at higher speeds. It is also incredibly compact in size and weight. In the future, it is hoped that this kind of wheel bearing will be used within satellites, stabilizing their attitude control to an even greater extent.

More info on CSEM’s and Kistler’s >>

Ref 1: Novel Generalized Notch Filter for Harmonic Vibration Suppression in Magnetic Bearing Systems