July 16, 2020

Collaboration with Axetris

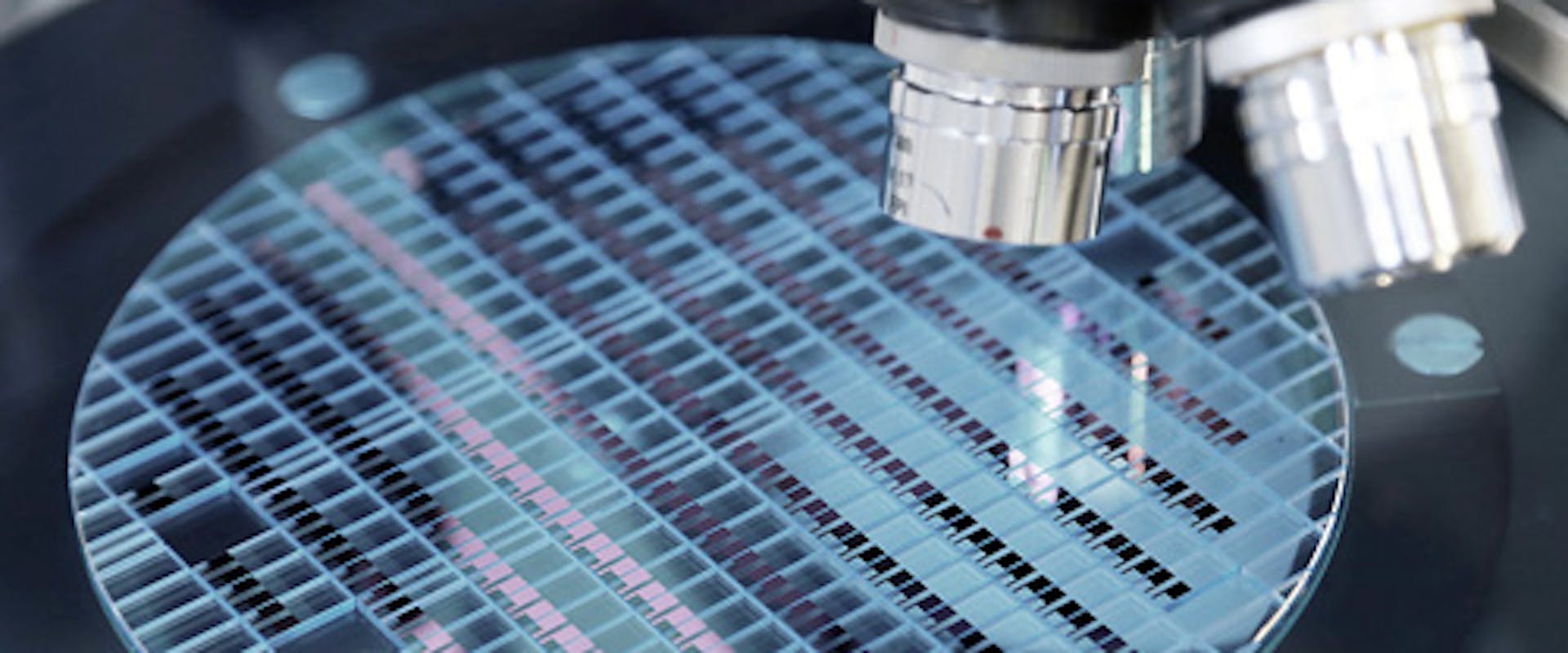

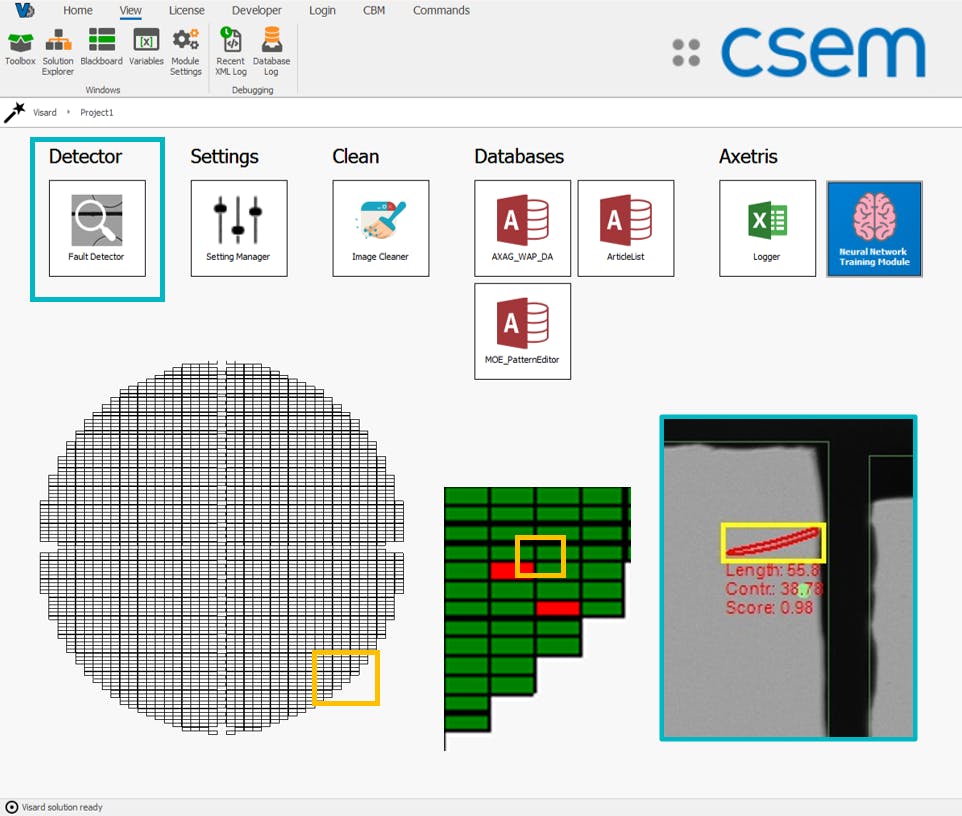

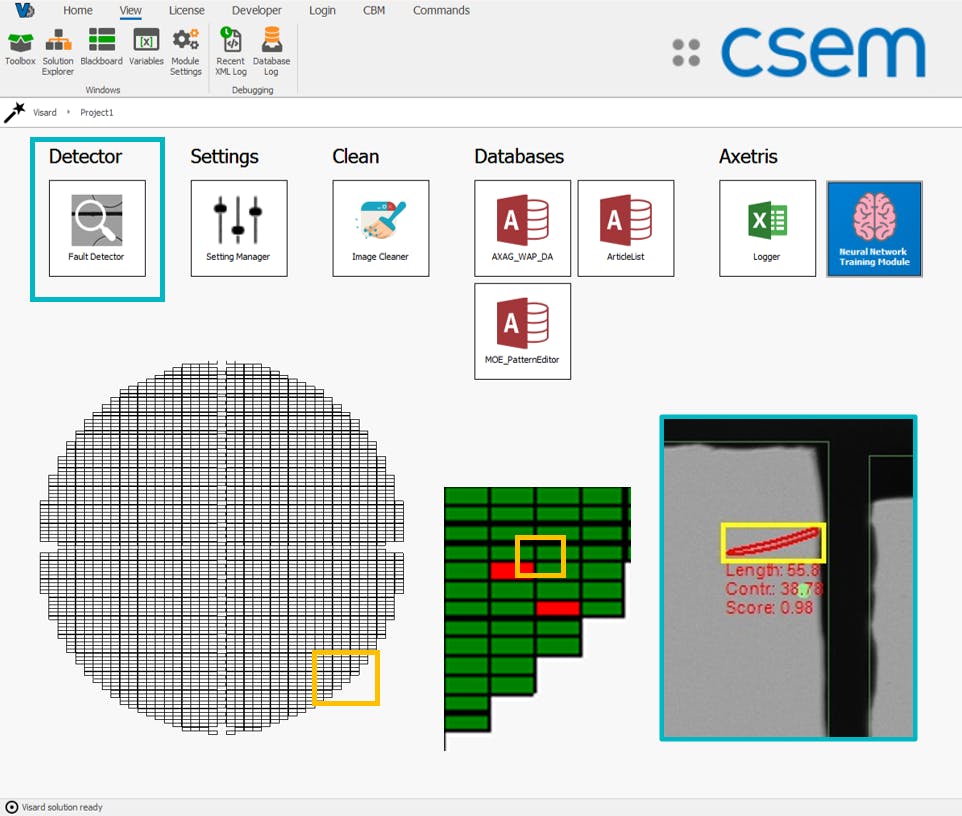

CSEM’s latest collaboration with Axetris AG has led to the development of a state-of-the-art and user-centric quality control (QC) platform. It utilizes advanced Neural Network (NN) and Machine Learning (ML) technologies alongside CSEM’s VISARD program to detect, diagnose, and categorize faults on Micro-Electro-Mechanical (MEMs) or Micro-Optic (MO) dies. Capable of lifelong learning, the system is easily adaptable and can be trained to cope with changes in production processes or fault criteria.