1 December 2025

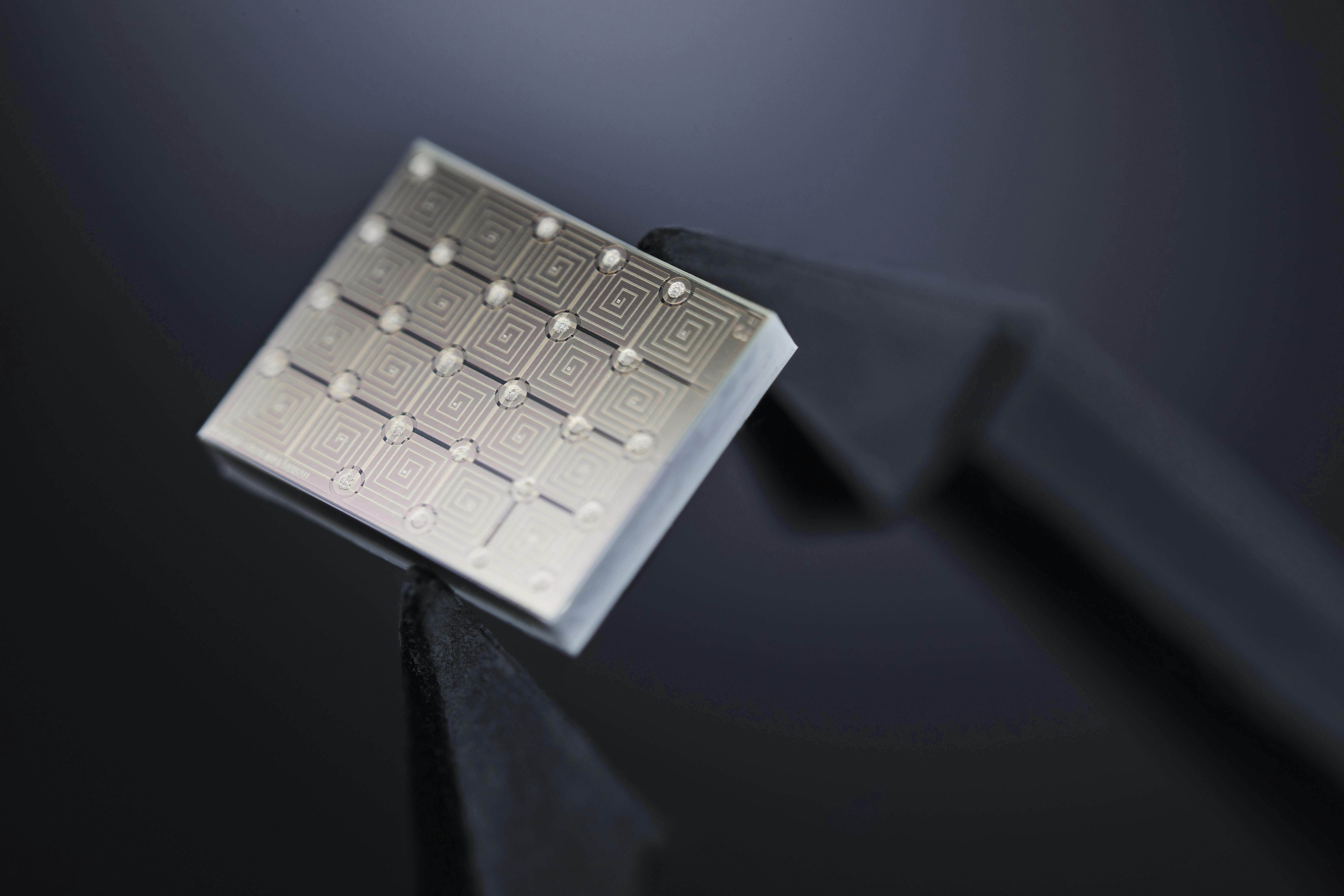

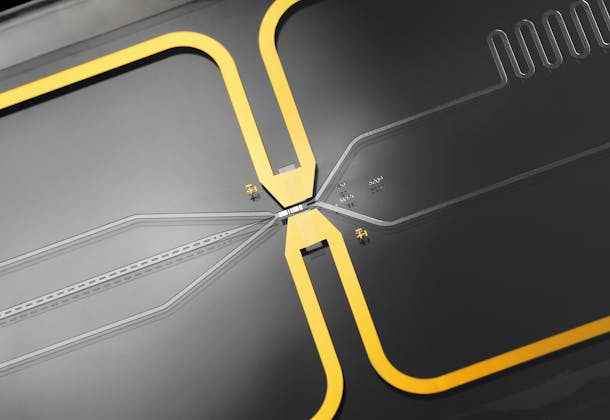

A biodegradable smart sensor to monitor sensitive goods

GREENsPACK is a sustainable smart sensing tag that can be used to signal when shipments of medicines or food have exceeded a safe threshold temperature. The tag was presented in the scientific journal Nature Communications.