12 June 2024

CompPair, Com&Sens and CSEM join forces for ESA CASSANDRA project

CompPair, Com&Sens and CSEM join forces to advance composite structural health monitoring and repair technology.

Adding value through nanotech

Surfaces and interfaces play a critical role in numerous chemical and physical processes, often holding the key to exploiting the full potential of new materials and their applications in fields as diverse as energy harvesting and storage, space aeronautics, watchmaking, and bio- and med-tech.

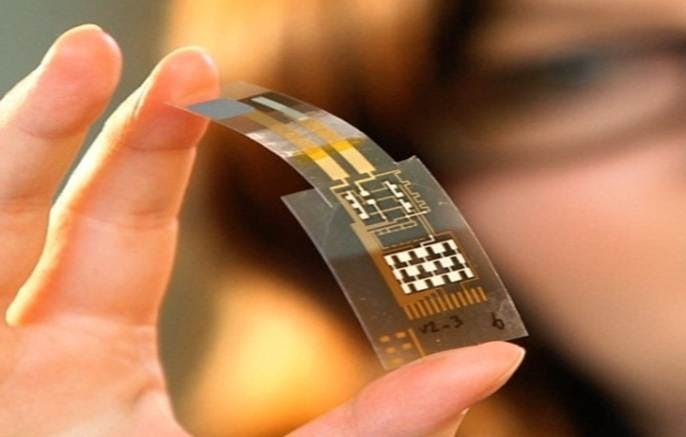

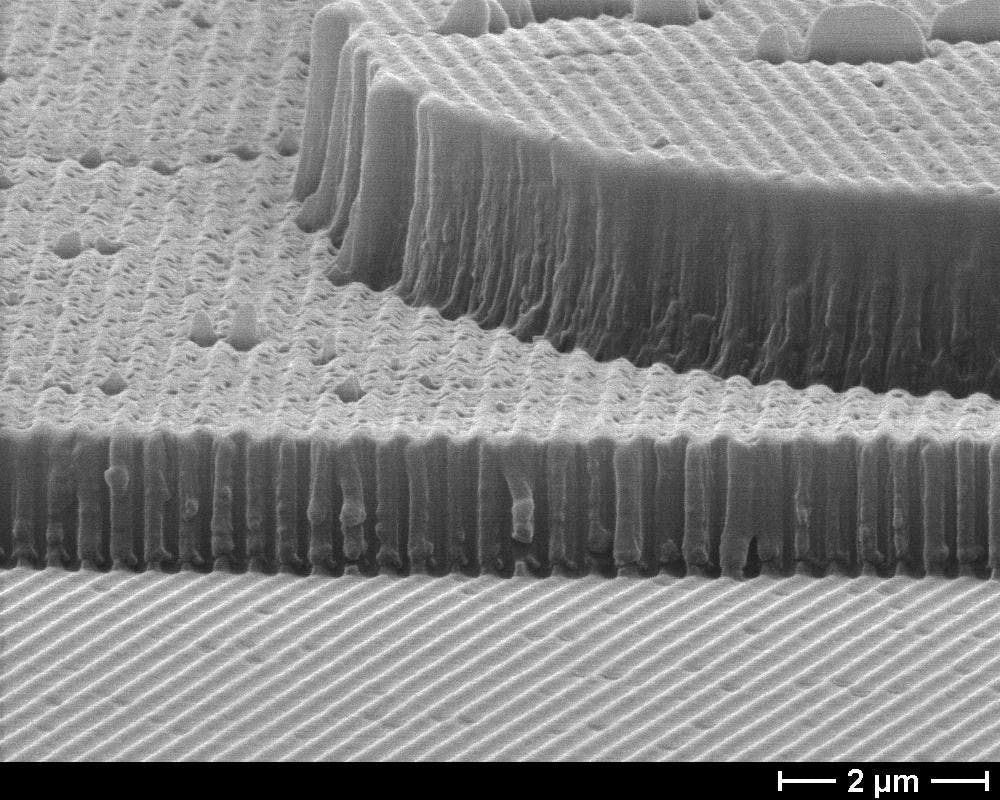

Surface functionality is affected by both its morphology and chemical composition. That’s why we specialize in nano-structuration, surface modification, and interfacial engineering to transform the nature of surfaces to suit your needs. We develop advanced technologies, which tailor the mechanical, electrical, optical, or wetting properties and functionality of surfaces by modifying their structures and chemical composition, as well as the associated upscaling platforms.

Our solutions will help you perfect the characteristics of a wide range of surfaces and materials. Here are some of our competencies:

Formulation of functional materials

Micro- and nano-structuration of surfaces

Surface and interface chemical functionalization

Our innovative approach to nano-engineered coatings and surfaces has led to breakthroughs in MEMS and packaging; Life Sciences tools; energy storage; and PV and solar buildings. Our experience and expertise range across multiple fields, such as aeronautics, aerospace, biotechnologies, watchmaking and energy, making CSEM the partner of choice when it comes to developing novel surfaces and engineering interfaces.

Get in touch to find out how we can create the perfect surface for any application.