Get in touch with our experts

Have questions or need more information? Learn more about our microfabrication services. Contact our team of experts today and get personalized assistance with your microlens array or on-chip lens projects.

At CSEM, our expertise covers the entire development cycle, from microlens design & specifications, tooling and prototyping to small and medium volume production. Whether you require a complete development, design inputs, or just microlens masters/tools, we are here for you.

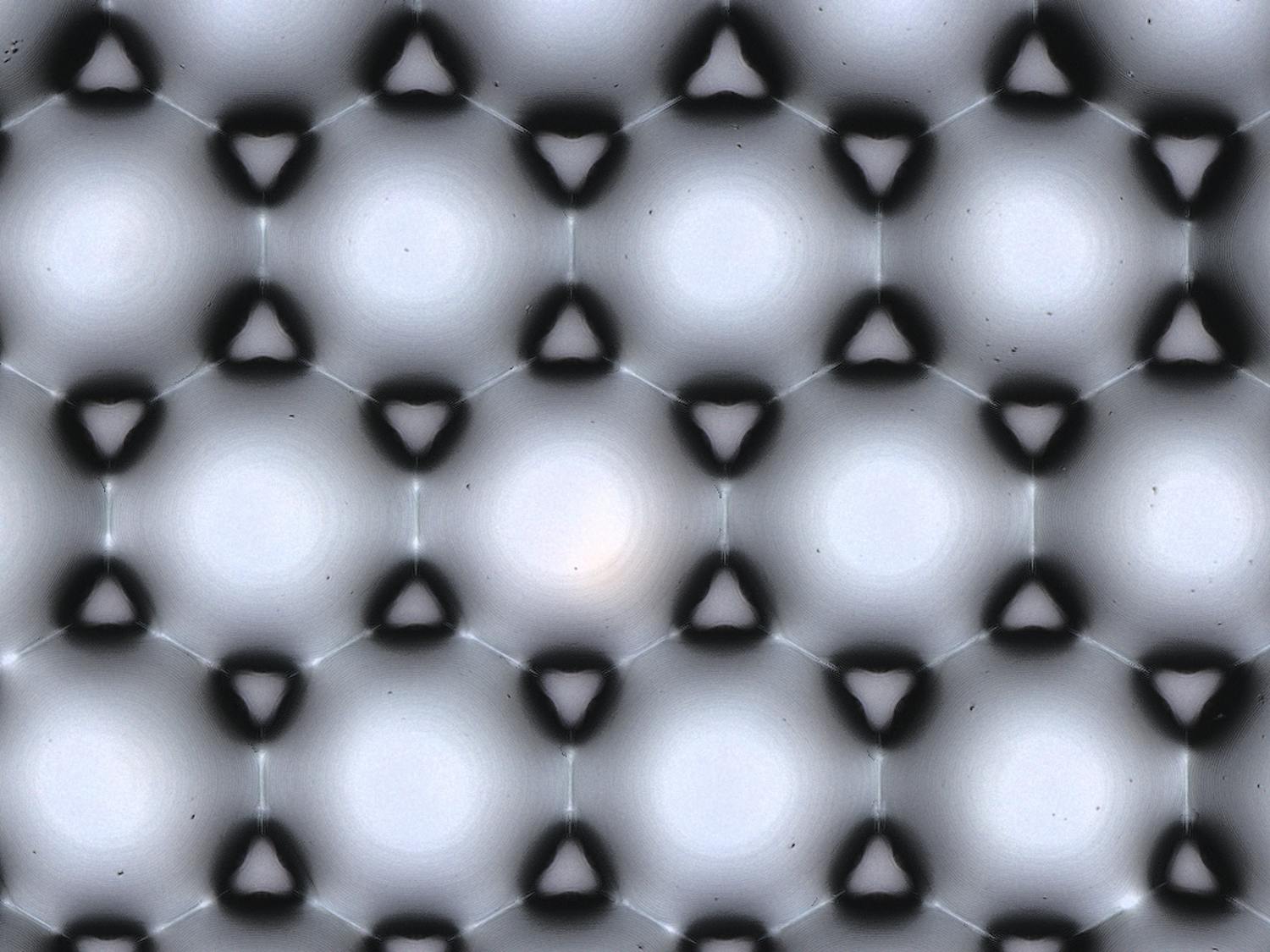

While many semiconductor foundries can provide standard photoresist-based microlens arrays (MLAs) for small pixel imagers (e.g. for smartphone cameras), more advanced and custom micro-optics solutions are not easily accessible. However, well adapted MLAs enable boosting of the collection efficiency of advanced imagers such as Single Photon Avalanche Diodes (SPADs) and silicon photomultipliers (SiPMs), thereby also boosting their photosensitivity dramatically. On light emitters, well designed and aligned MLAs provide a much better emission by collimating light beams from VCSELs, micro-LEDs and from/to Photonics Integrated Circuits (PICs). Whether you have full wafers, only a few chips, or are at the design phase, we can help you enhance your device performance with customized micro-optics.

A standard project comprises three phases, each of them subject to customer approval and potential further iterations for optimization.

Based on the required parameters for each individual case, we perform modeling, simulations (ray tracing) and tolerancing to identify the microlens geometry which maximizes performances. This includes an analysis of the active wafer to be microlensed and the optical and environmental specifications.

This Zemax 3D model used in the microlens design process showcases a 3 by 3 microlens array with its residual layer on top of a 3 by 3 single photon avalanche diodes (SPAD) array. This comprises, from top to bottom: a grid modeling the front-side interconnects, a passivation layer, an intermediate layer and a crystalline silicon layer embedding circular photodiode active areas. DOI

Sketch illustrating the MLA UV-replication process: The MLA mold produced in the second MLA tooling phase is aligned in a mask aligner to the customer’s chip/wafer. The selected microlens material is dispensed in liquid state. Then the microlens material is imprinted and UV cured. Finally, the registered MLA is demolded.

Have questions or need more information? Learn more about our microfabrication services. Contact our team of experts today and get personalized assistance with your microlens array or on-chip lens projects.

F. Zanella, et al., Advanced microlens origination by thermal reflow, Proc. SPIE PC12898, PC1289805, Presented at SPIE OPTO (2024). DOI

C. Bruschini, et al., Challenges and prospects for multi-chip microlens imprints on front-side illuminated SPAD imagers, Optics Express, 31 (13), 21935-21953 (2023). DOI

T. Offermans, et al., PHABULOuS: manufacturing of large surfaces with free-form micro-optics, In Digital Optical Technologies 2023 (Vol. 12624, pp. 96-101). SPIE. DOI

F. Zanella, et al., Optimization of microlens arrays for photon detectors. In Quantum Optics and Photon Counting 2023 (p. PC1257005). SPIE. DOI

F. Zanella, et al., UV-replicated microlenses for quantum devices. In : Quantum Sensing and Nano Electronics and Photonics XIX. SPIE, 2023. p. 55-58. DOI

F. Zanella, et al., Manufacturing acceleration of free-form micro-optical arrays (FMOAs) with CAD algorithms. In Advanced Fabrication Technologies for Micro/Nano Optics and Photonics XVI (Vol. 12433, pp. 91-96). SPIE 2023. DOI

C. Bruschini, et al., High-efficiency fill factor recovery using refractive microlens arrays imprinted on 0.5-256 kpixel front-side illuminated SPAD imagers, Advanced Fabrication Technologies for Micro/Nano Optics and Photonics XVI. Vol. 12433. SPIE, 2023. DOI

F. Zanella, et al., Increasing the quantum efficiencies of advanced photonics imagers with microlens arrays. Precision Photonic Systems, 22 (2022) DOI

F. Zanella, et al., Microlens testing on back-illuminated image sensors for space applications, Applied Optics, 59, 3636-3644 (2020). DOI

J. Mata Pavia, et al., Measurement and modeling of microlenses fabricated on single-photon avalanche diode arrays for fill factor recovery, Optics Express, 22, 4202-4213 (2014). DOI

M. T. Gale, et al., Replication technology for optical microsystems, Optics and Lasers in Engineering 43 (2005) 373–386, DOI

C. Gimkiewicz, et al., Wafer-scale replication and testing of micro-optical components for VCSELs, Proceedings of SPIE Vol. 5453 (SPIE, Bellingham, WA, 2004) · 0277-786X/04/$15, DOI