Contact

Get in touch to find out how you can get more out of your MEMS today.

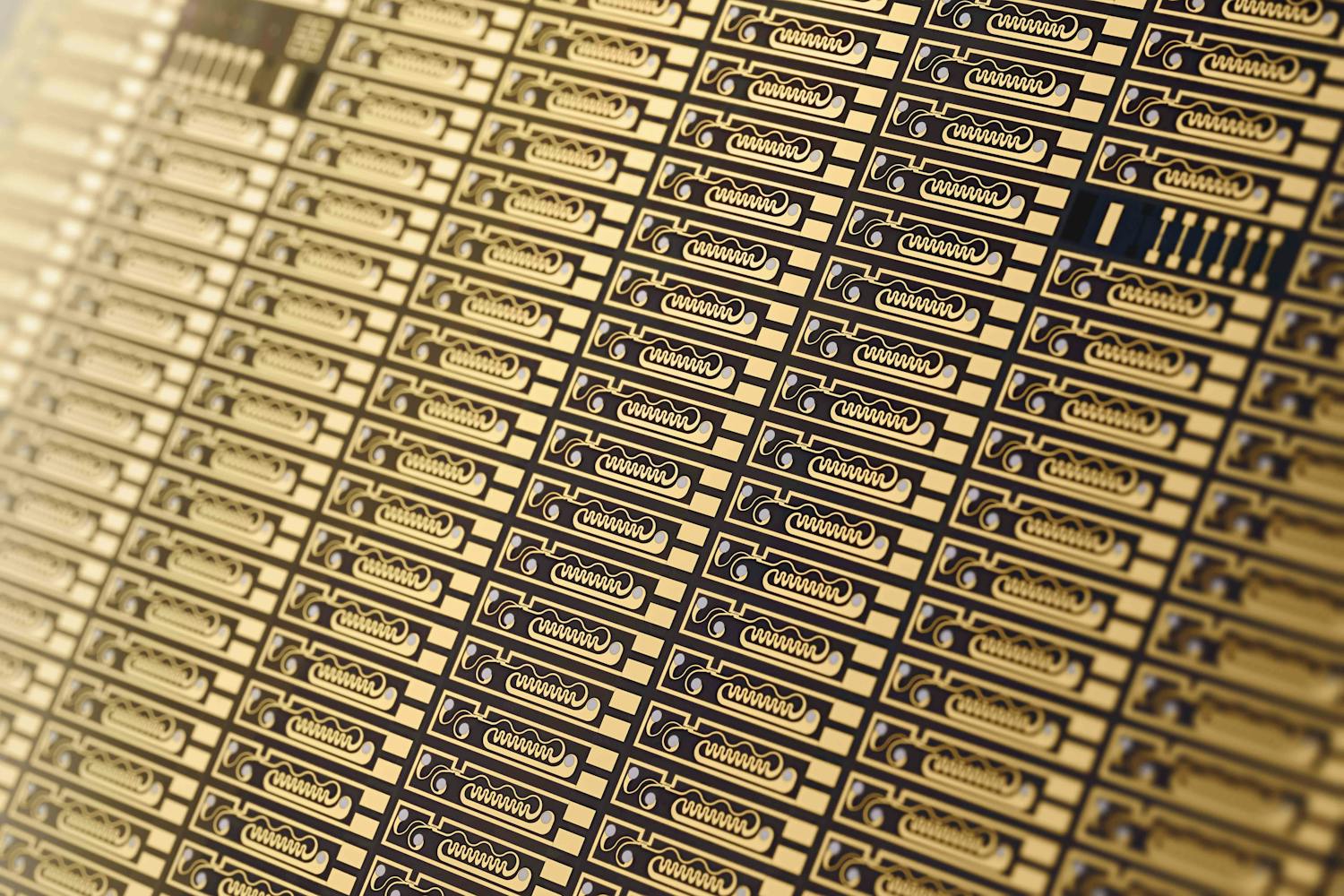

We have more than 30 years of experience in a variety of demanding fields including photonics, life sciences, watchmaking, and harsh environments. Our experienced and tenured team supports our partners with a flexible mindset, strengthened by a state-of-the-art 150 mm wafer clean room.

At CSEM, our expertise covers the entire development cycle, from MEMS design to process industrialization and small to medium volume production. Whether you need a complete development, some design inputs, or just a few thin-film depositions, we are here for you.

Thanks to our flexibility and deep understanding of new processes, we specialize in prototyping and industrializing the next generation of MEMS, microfluidics, and photonic devices. We facilitate and accelerate the innovation of our start-ups, SMEs, and multinational partners.

We are constantly developing and maturing new technological building blocks, processes, and materials to anticipate industry needs and trends. You have the vision, we have the tools and expertise to make it happen.

Get in touch to find out how you can get more out of your MEMS today.