3 December 2025

BUSS–a world leader in compounding–wins CSEM'S Digital Journey award 2025

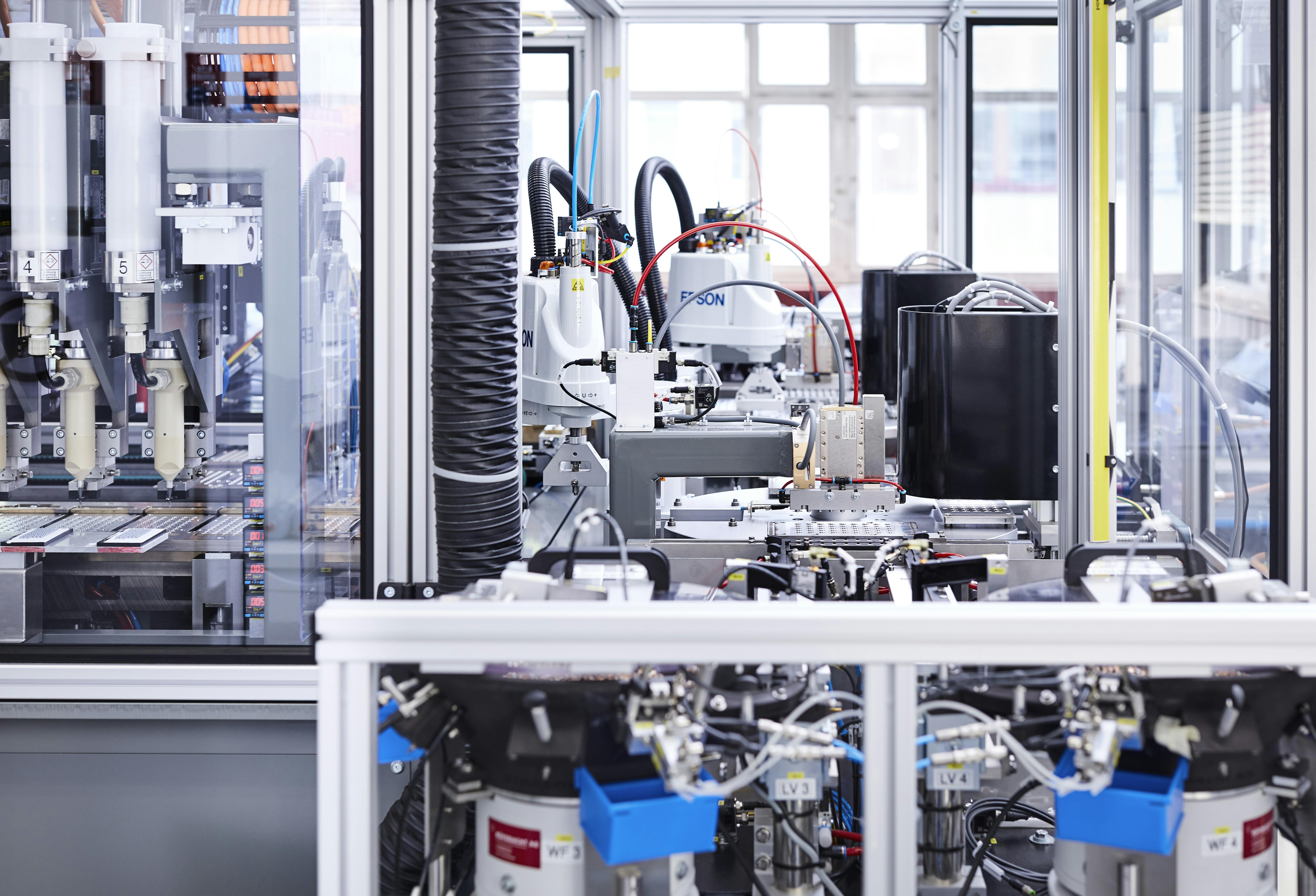

Swiss SME BUSS has won CSEM’s Digital Journey Award 2025 with its Predictive Quality project. By adding industrial AI to SenseHUB®, BUSS aims to predict quality in real time and reduce waste and downtime.