Ready to reduce the impact of microvibrations on your high-precision systems?

Contact CSEM’s microvibration experts to plan your test campaign or explore custom isolation solutions.

The term "microvibration" refers to mechanical vibrations with amplitudes and frequencies that impact the correct operation of surrounding susceptible systems.

Microvibrations pose significant challenges in various fields, particularly in space and aerospace, where mission-critical operations demand exceptional mechanical stability. Understanding, measuring, and mitigating microvibrations is essential to ensure the reliable operation of high-precision mechanisms and scientific instruments.

Through dedicated testing and characterization, engineers can detect, measure, and isolate these disturbances. Microvibration testing enables teams to qualify components, optimize mechanical designs, and implement active or passive isolation solutions, ensuring that the spacecraft performs reliably under the dynamic conditions of space.

By performing microvibration analysis, engineers can ensure that scientific instruments, optical systems, and other critical payloads maintain their intended performance, even under challenging conditions.

CSEM’s dedicated microvibration testing facility provides a wide variety of services for:

These services help clients understand, quantify, and reduce microvibration effects through design modifications or isolation strategies.

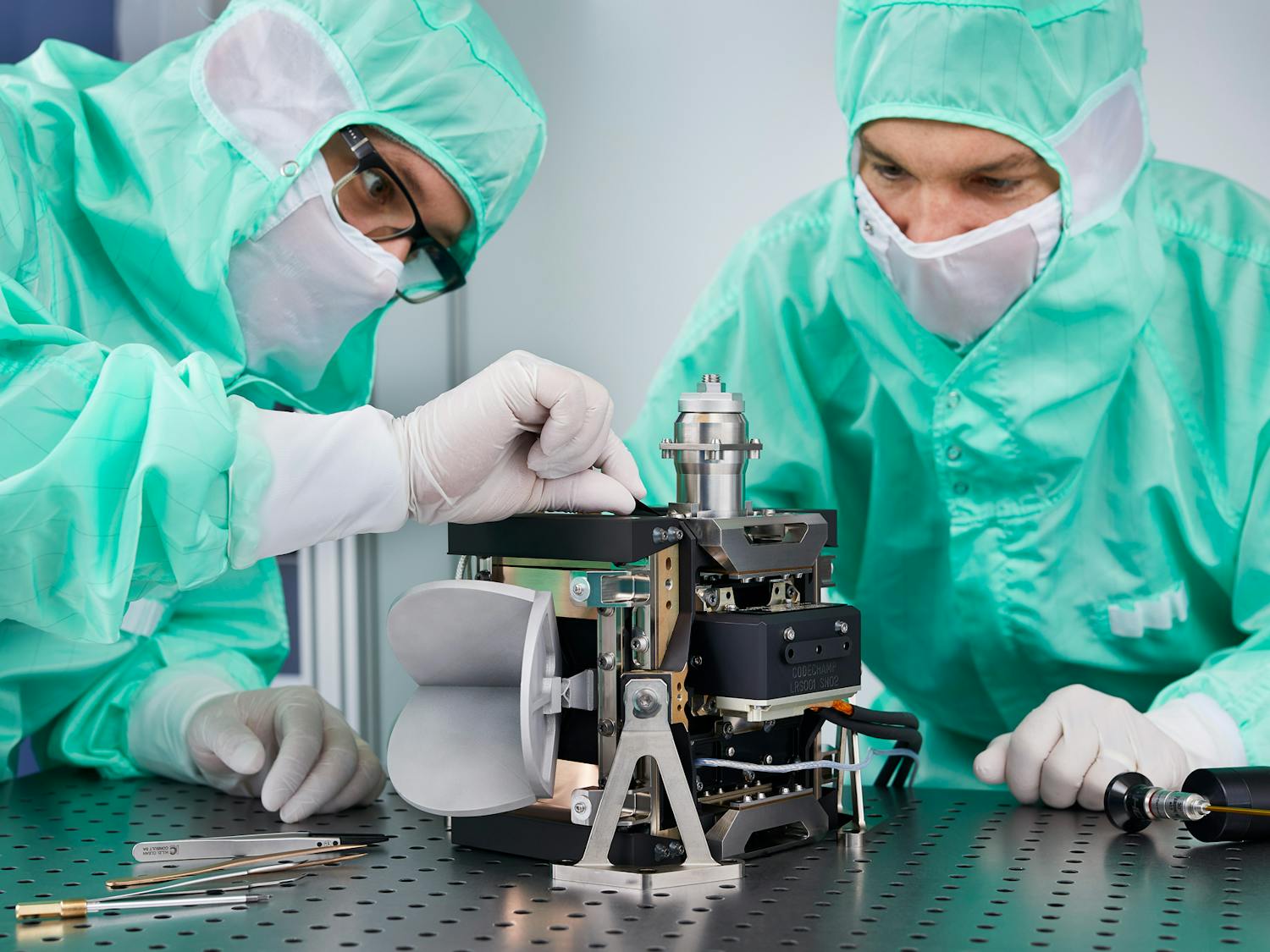

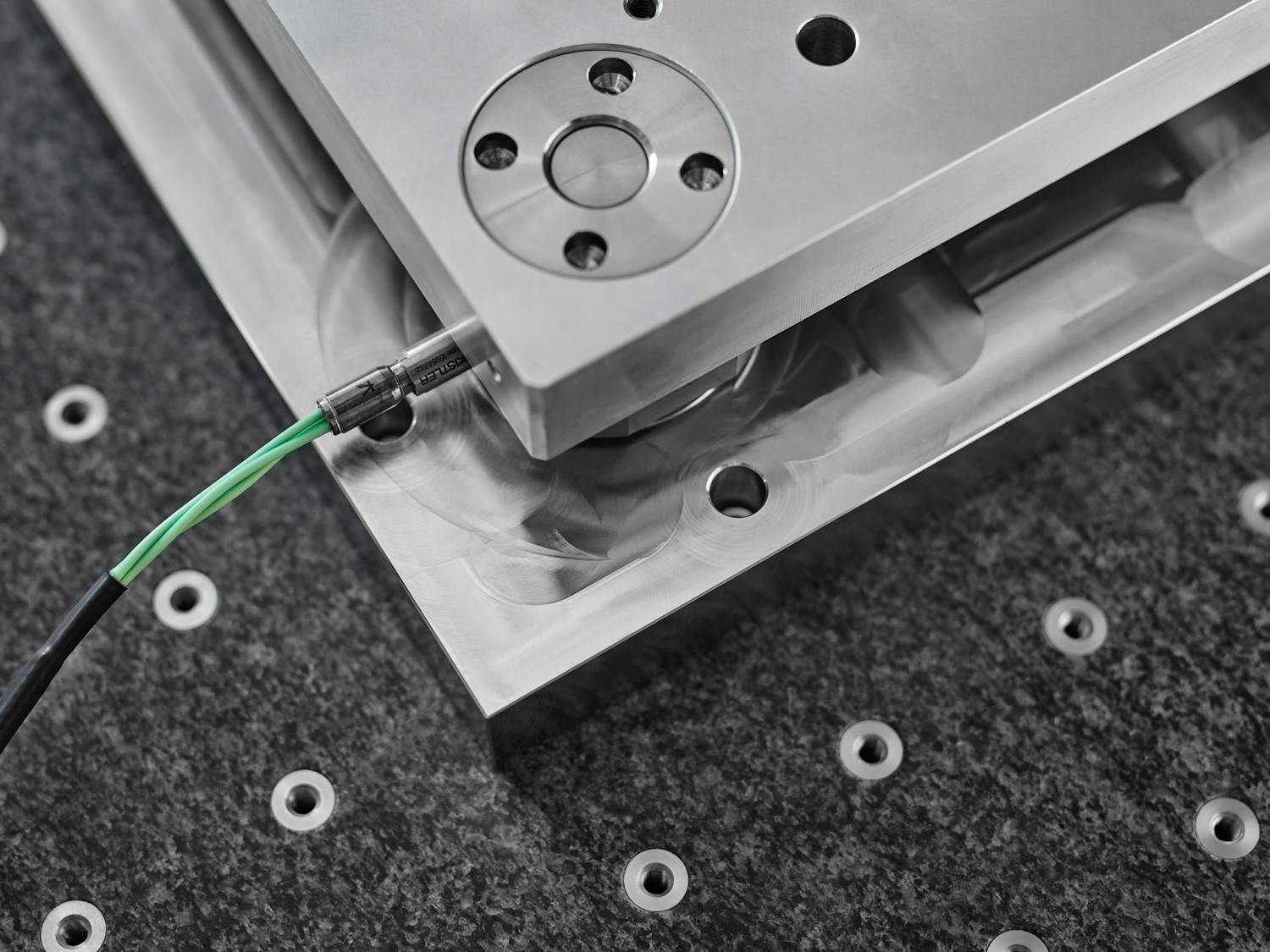

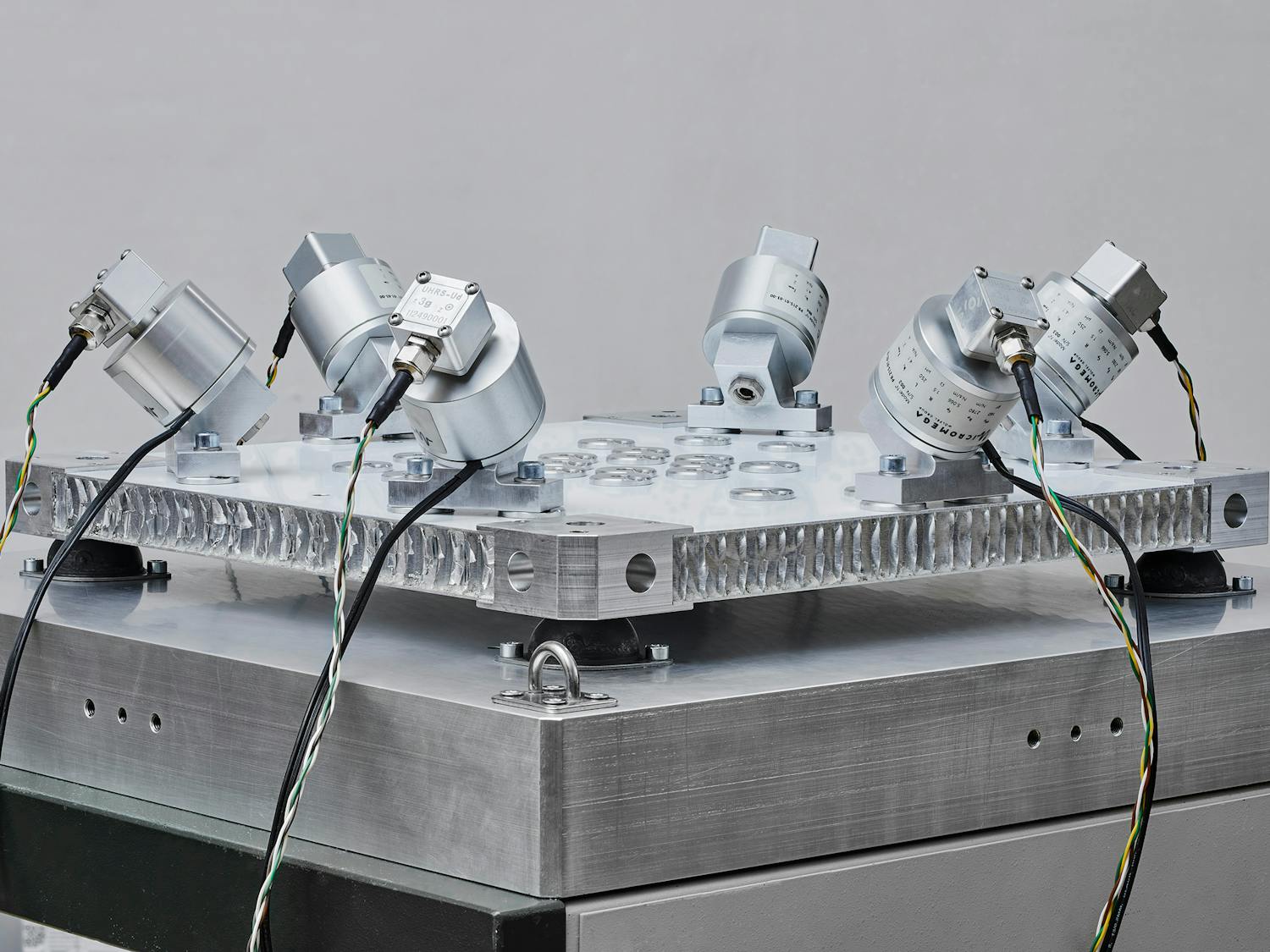

The exported microvibration characterization setup consists of a custom-designed multicomponent dynamometer built with:

System configuration

The dynamometer is mounted on top of a granite seismic mass, supported by four pneumatic isolators. This shields the setup from building vibrations that could contaminate measurements. The sensor array is positioned between two plates—a lower plate interfacing the dynamometer with the granite table and an upper plate designed to support various test components. Two different upper plate sizes are available depending on payload geometry.

👉 Download the technical datasheet of our exported microvibration testing setup, including sensor characteristics, mounting configurations, and system performance.

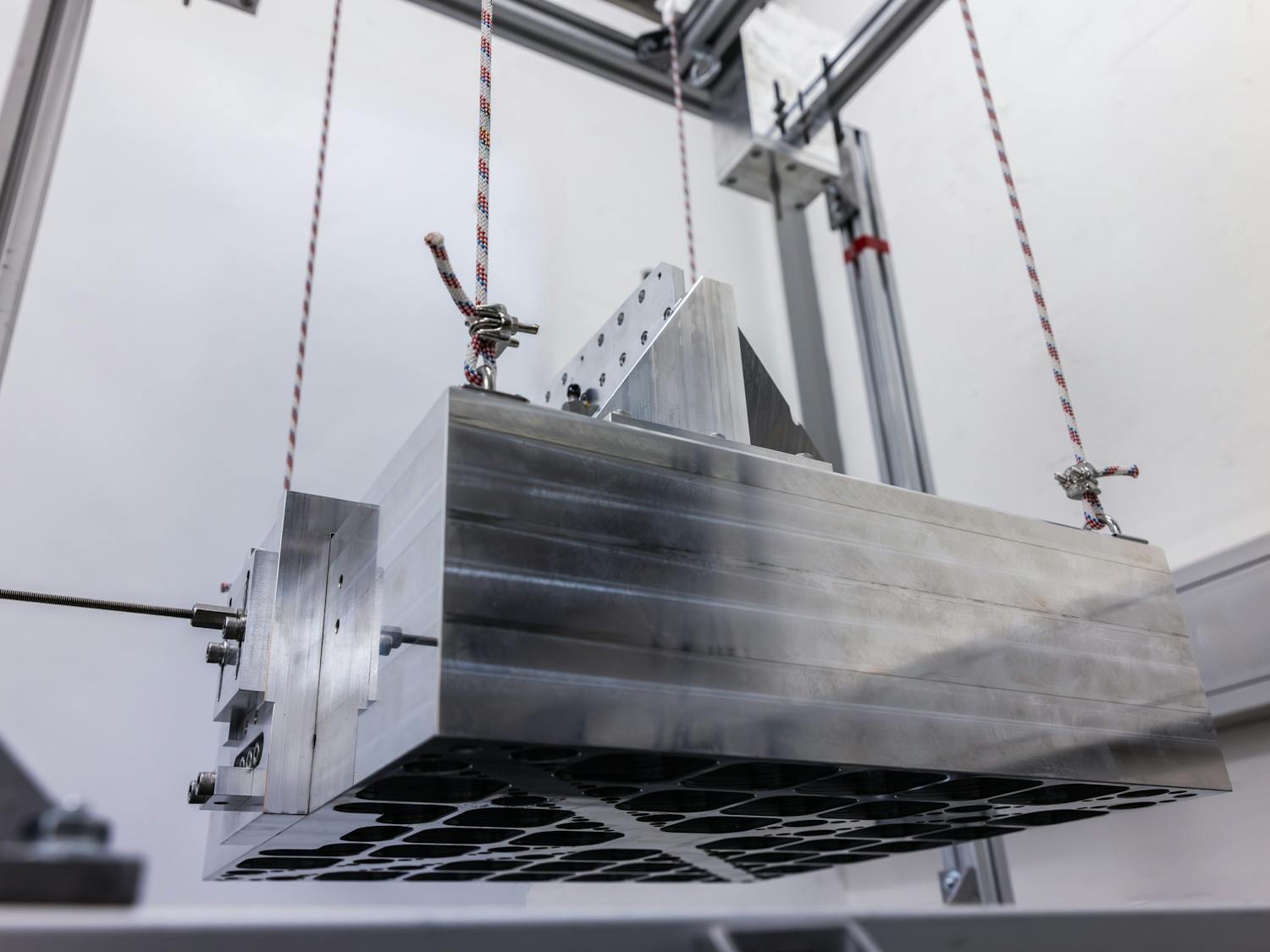

The second-generation microvibration susceptibility test system is designed to assess how susceptible devices respond to external vibrational disturbances. The setup features a granite seismic base supported by four pneumatic isolators. A cage surrounds the setup, supporting a suspended platform where the device under test is mounted.

The design is optimized to improve performance by minimizing transmission of environmental noise and building vibrations to the test system and decoupling the test setup from surrounding disturbances to ensure high-fidelity measurements.

Key features include:

Multiple accelerometer options are available to cover a wide frequency range and amplitude.

This setup enables the validation of a device's performance under microvibration conditions representative of space environments.

👉 Download the technical datasheet for our susceptibility test platform, optimized for validating susceptible components under microvibration environment.

CSEM develops custom active, semi-active, and passive solutions for the isolation of components generating or susceptible to microvibrations. For applications with stringent stability requirements, passive isolation alone may be insufficient—requiring active technologies to achieve the targeted performance.

An example is MIVIDA, a hybrid (active and passive) microvibration isolation system developed at CSEM to

Read more on IEEE Transactions on Control Systems Technology - Data-Driven LPV Control for Harmonic Disturbance Rejection in a Hybrid Isolation Platform (this paper isn’t accessible for free, subscription is needed).

CSEM supports space and aerospace clients through:

The microvibration test setup was developed in collaboration with ESA under its Technology Development Element (TDE) program to enhance prediction and verification methods for modeling microvibrations. Learn more on ESA’s official page: Microvibration_Test_Setup.

Contact CSEM’s microvibration experts to plan your test campaign or explore custom isolation solutions.

Get in touch with our specialists — we’re happy to help you evaluate your mission requirements