Ready to revolutionize your quality inspection process?

Contact us today to discuss your needs.

In today's competitive industrial landscape, ensuring the highest level of product quality is paramount for businesses to thrive.

(Cet article n'est disponible qu'en anglais)

At CSEM, we specialize in providing comprehensive and reliable industrial quality inspection solutions. We base these on deep learning algorithms and deploy them across a wide range of industries. Our solutions are designed to address the unique challenges faced by industries, including coping with small amounts of training data or even "lot size one" applications. CSEM understands the importance of efficient algorithms and advanced hardware setups that can access 3D or hyperspectral information directly, enabling accurate and effective quality inspection.

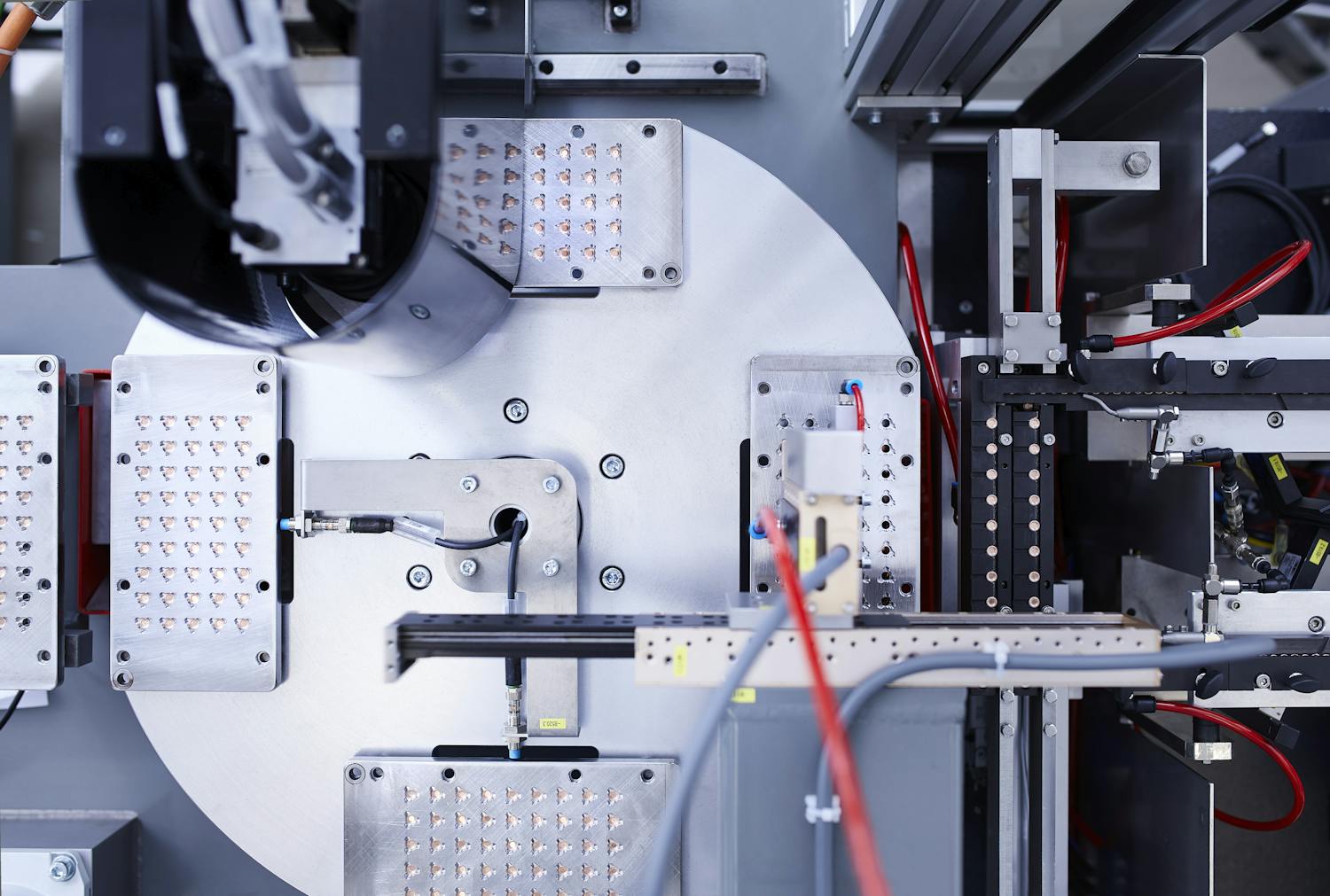

Hardware plays a vital role in these processes by providing the necessary equipment and tools for inspections, measurements, and tests. CSEM’s vision setups utilize a diverse range of sensor technologies, such as 2D or 3D cameras, optical coherence tomography (OCT), multi/hyperspectral sensors, and different polarization methods. These components, whether off-the-shelf or fully customized, are carefully selected to meet the specific needs of each inspection task. Additionally, we integrate tailored illumination solutions into the vision setup to enhance sensing methods and ensure accurate and reliable data capture.

The data pipeline is crucial for industrial inspection solutions as it facilitates the seamless flow of data through various stages. From acquisition to storage, management, visualization, logging, and archiving, CSEM’s data pipeline ensures efficient and effective handling of inspection data. By collecting and storing data efficiently, it becomes easily accessible for visualization and analysis.

Furthermore, logging data enables traceability and future reference, while proper data management enhances decision-making during the development and production phases. Whether the data is processed on the edge, on a local server, or in a public cloud, the pipeline always adapts to your business needs. By leveraging data assets, businesses can extract valuable insights to drive improvements in their processes.

Algorithms play a pivotal role in industrial quality inspection, covering various stages of the inspection process. Pre-processing techniques are employed to enhance data quality by reducing noise and extracting relevant features for subsequent analysis. Classical algorithms, such as metrology, enable precise measurements, dimensional analysis, and defect detection. To address the complexities posed by diverse product ranges, complex defects, and high production speeds, we fine-tune our deep learning algorithms to recognize and classify complex patterns, defects, or anomalies.

Additionally, our algorithms are designed to be adaptable over time, supporting life-long learning for continuous improvement and adaptation to evolving inspection requirements. Our experts are already working on the next generation of quality inspection techniques, which combine multimodal vision data with time-series signals from various sensors. This enables a holistic view of the machine or process to monitor perfect quality.

In our pursuit of excellence in industrial quality control, we continuously strive to enhance existing data sets. We achieve this by creating photorealistic images using advanced rendering software like Unity and Blender and further adapting them with Generative Adversarial Networks (GANs) to simulate real-world conditions.

By leveraging synthetic data generated in combination with existing data sets, we can create more robust and generic solutions while minimizing the effort and cost associated with collecting real data. CSEM quickly adapts the most promising algorithmic approaches from academia, optimizes them for our customers, and takes care of deployment for industrial needs. This approach enables us to deliver even more reliable and efficient quality inspection solutions to our clients.

CSEM develops advanced technologies for industrial quality inspection, integrating high-resolution imaging, multispectral sensing, and embedded AI for in-line, non-destructive evaluation. These systems are designed to support automated decision-making, reduce reliance on manual inspection, and improve defect detection accuracy across diverse materials and production environments. Through its applied R&D approach, CSEM provides robust, scalable inspection technologies tailored to the specific constraints and requirements of modern manufacturing systems.

Contact us today to discuss your needs.

Our groundbreaking research and technological advancements have revolutionized industrial quality control. Explore them now.