Let’s build the next generation of polymer solutions together

Ready to advance your polymer innovation? Request a technical consultation with our experts and explore what’s possible.

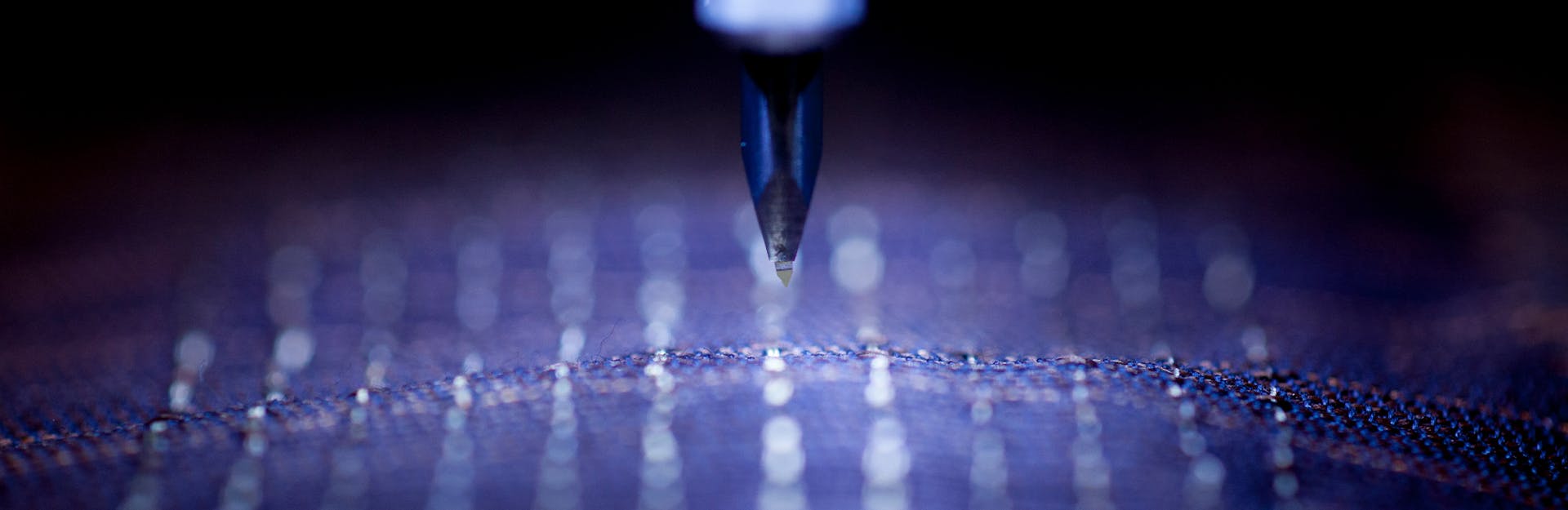

An integrated polymer R&D and validation platform combining formulation, compounding, extrusion, advanced characterization, and accelerated aging—built to move materials from concept to industrial readiness.

At the heart of the CSEM polymer materials development platform lies a state-of-the-art polymer material R&D laboratory dedicated to transforming ideas into high-performance materials. From formulation to industrially relevant validation, we support our partners across the entire innovation cycle with deep scientific expertise and pilot industrial-scale capabilities.

Our integrated platform combines polymer compounding, extrusion, advanced characterization, and accelerated testing, enabling rapid development, optimization, and qualification of tailor-made polymer material solutions. Whether to improve performance, enhance reliability, or accelerate time-to-market, our teams work alongside you to deliver measurable results. To date, our platform has supported leading PV manufacturers, luxury brands, and industrial partners to develop next-generation polymer films, coatings, and multilayer structures.

Innovation does not stop at material formulation. By combining scientific rigor, application expertise, and industrial realism, we help partners transition confidently from early concepts to validated material solutions.

Our laboratory is not simply a testing facility—it is a collaborative innovation space where ideas evolve into qualified, high-performance polymer systems ready for industrial deployment. By integrating formulation, compounding, extrusion, characterization, and accelerated aging under one roof, we enable faster development loops and reduce validation risk.

Whether to design new material, benchmark an existing product, or validate long‑term reliability under demanding outdoor conditions, our experts guide you from the first feasibility check to industrial readiness.

CSEM offers an integrated development and testing environment, combining a comprehensive range of R&D and pilot-line possibilities:

Our equipment and methodologies allow us to simulate real-world conditions and validate materials in demanding environments. This unique combination within a single workflow enables faster iteration, deeper material understanding, and reduced risk—especially for partners requiring validated long‑term stability. This allows companies to derisk innovation and bring qualified materials to market faster.

Our R&D services support a wide range of industries where performance, durability, and innovation are critical:

Our current projects include PV encapsulation materials, polymer coatings for premium brands, multi-layer films for demanding environments, and fiber-based solutions requiring tailored additive packages or reliability validation.

Ready to advance your polymer innovation? Request a technical consultation with our experts and explore what’s possible.

Our polymer platform is used by industrial partners in the photovoltaic sector, supporting the development of encapsulants, backsheets, frontsheets, and functional polymer layers tailored for PV reliability and performance.

Additionally, companies in the luxury segment have shown interest in polymer coatings and fiber‑related developments, as have automotive and aerospace suppliers evaluating durable multi‑layer structures and material producers looking to accelerate formulation optimization or verify additive systems.