29 mars 2023

CSEM joins a key consortium of ASTM International’s Additive Manufacturing Center of Excellence

(En anglais uniquement)

CSEM has joined the ASTM International Consortium for Materials Data and Standardisation (CMDS) initiative, which is being run through the ASTM Additive Manufacturing Center of Excellence (AM CoE).

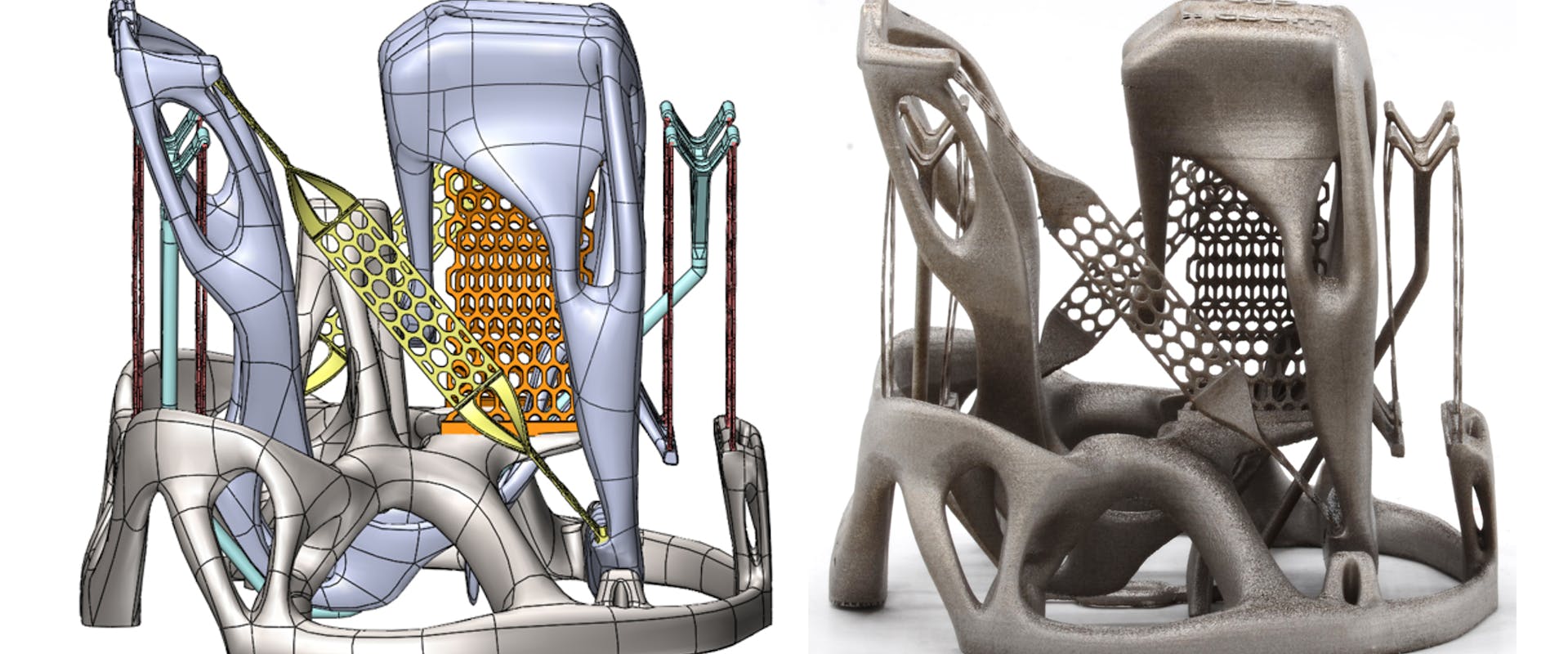

Example of a compliant mechanism for space applications developed at CSEM - Example of a compliant mechanism for space applications developed at CSEM