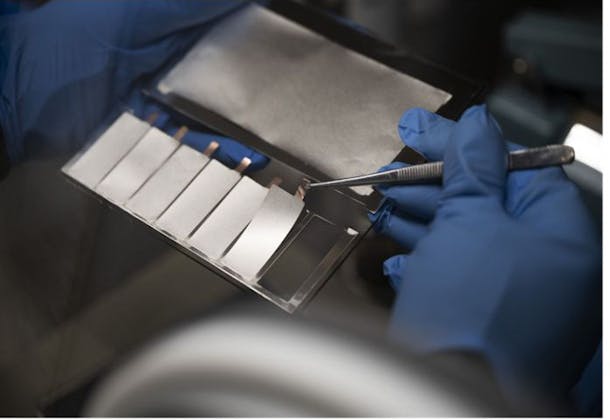

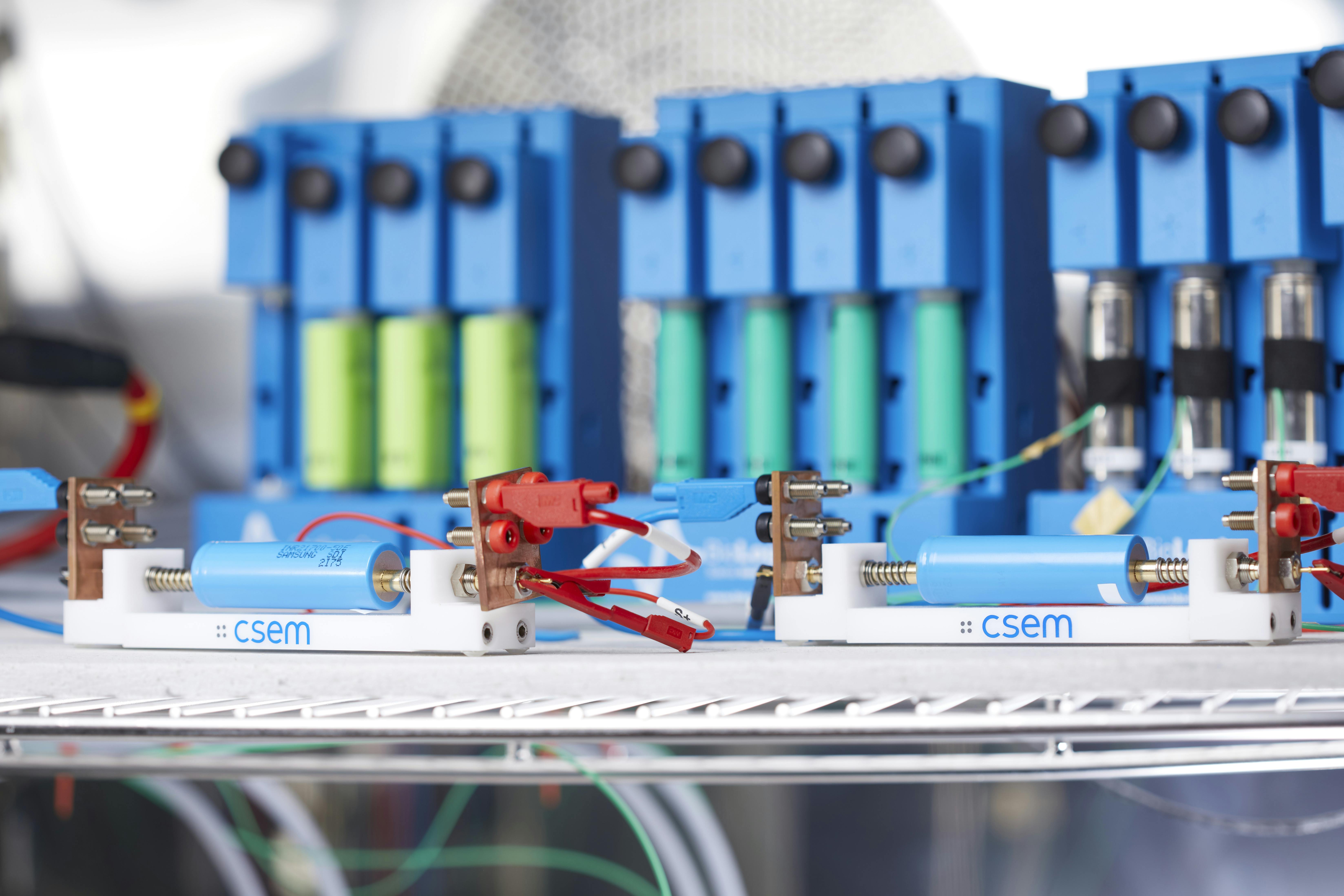

We are developing innovative sensors using sensorized cell and odd random phase electrochemical impedance spectroscopy (ORP-EIS) technology. Coupled with other sensing functions, such as pressure, ultrasound, and strain, we can detect faults and negative influences on battery life and performance at an early stage and therefore increase the performance of the li-ion batteries both for automotive and stationary applications.

Battery models

- Optimizing electrochemical energy storage batteries by performing extensive characterization with long-term cycling of up to several months

- Using electrochemical impedance spectroscopy (EIS) to improve electrochemical phenomena diagnostics

- Focusing on electrical modeling at the intersection between equivalent circuit models and electrochemical models

- Assessing the second-life potential of used cells and modules by using fast measurement cycles to accurately determine the remaining capacity