22 June 2023

Revolutionizing steel tracking: CSEM's AI solution for steel mills

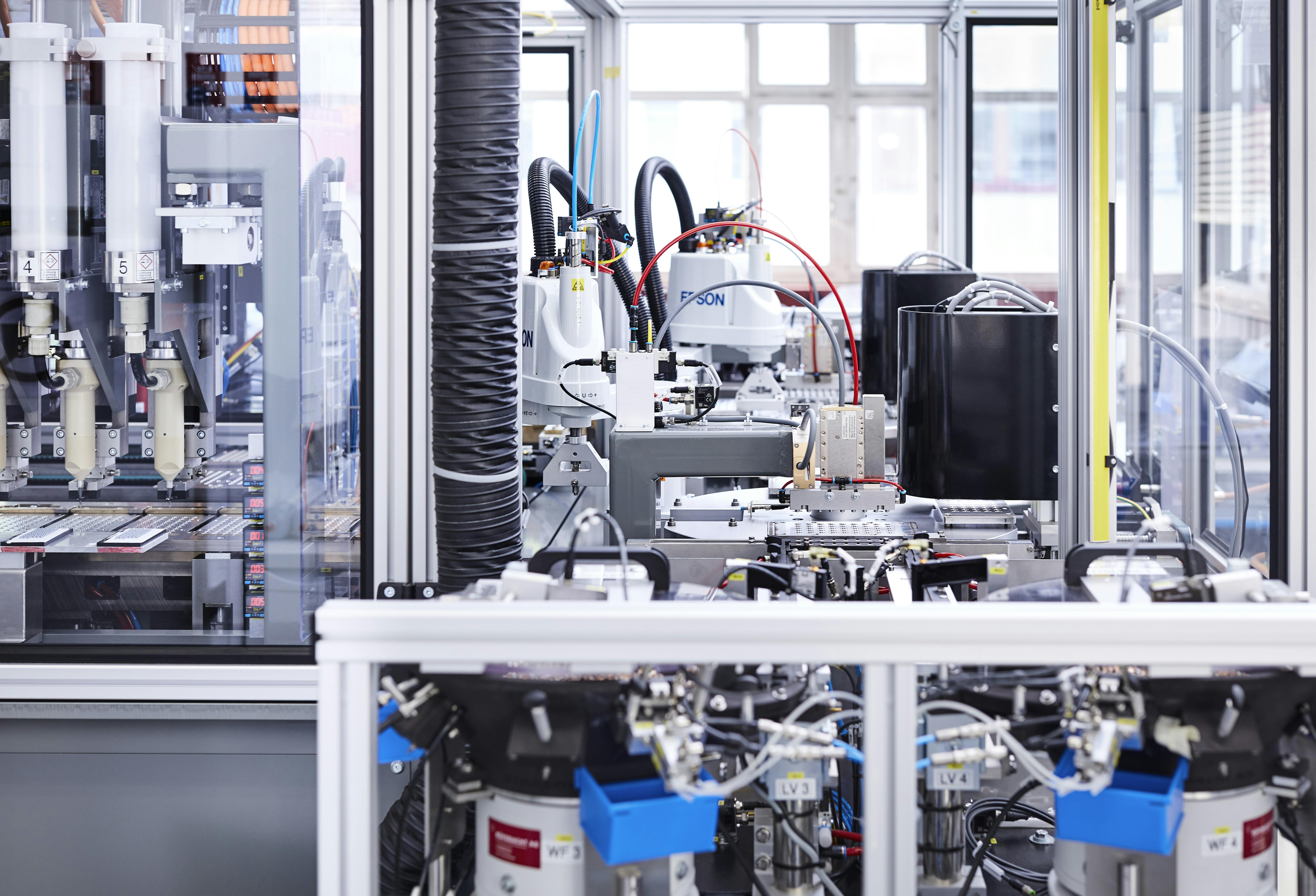

Swiss steel plant manufacturer SMS Concast partners with CSEM to introduce an advance artificial intelligence (AI) solution that can precisely identify steel products in challenging environments.